Siemens has developed four product lines to date: For example, the SIMATIC 505 could handle floating point quantities and trigonometric functions. More complex inputs, outputs, and calculations were also supported as the SIMATIC line developed. The programs on the SIMATIC devices respond in real time to inputs from sensors on the controlled machines, and send output signals to actuators on the machines that direct their subsequent operation.ĭepending on the device and its connection modules, signals may be a simple binary value ("high" or "low") or more complex. SIMATIC devices have input and output modules to connect with controlled machines. Similar to those on general-purpose digital computers to be stored and used for machine control. Microprocessors were introduced in 1973, allowing programs Early SIMATIC devices were transistor-based, intended to replace relays attached and customized to a specific machine. In a more lightweight and versatile manner than controls hard-wired for a specific SIMATIC devices are intended to separate the control of a machine from the machine's direct operation, Siemens SIMATIC S7-300 PLC CPU with three I/O modules attachedĪs with other programmable logic controllers, It is a portmanteau of “ Siemens” and “Auto matic”. The name SIMATIC is a registered trademark of Siemens.

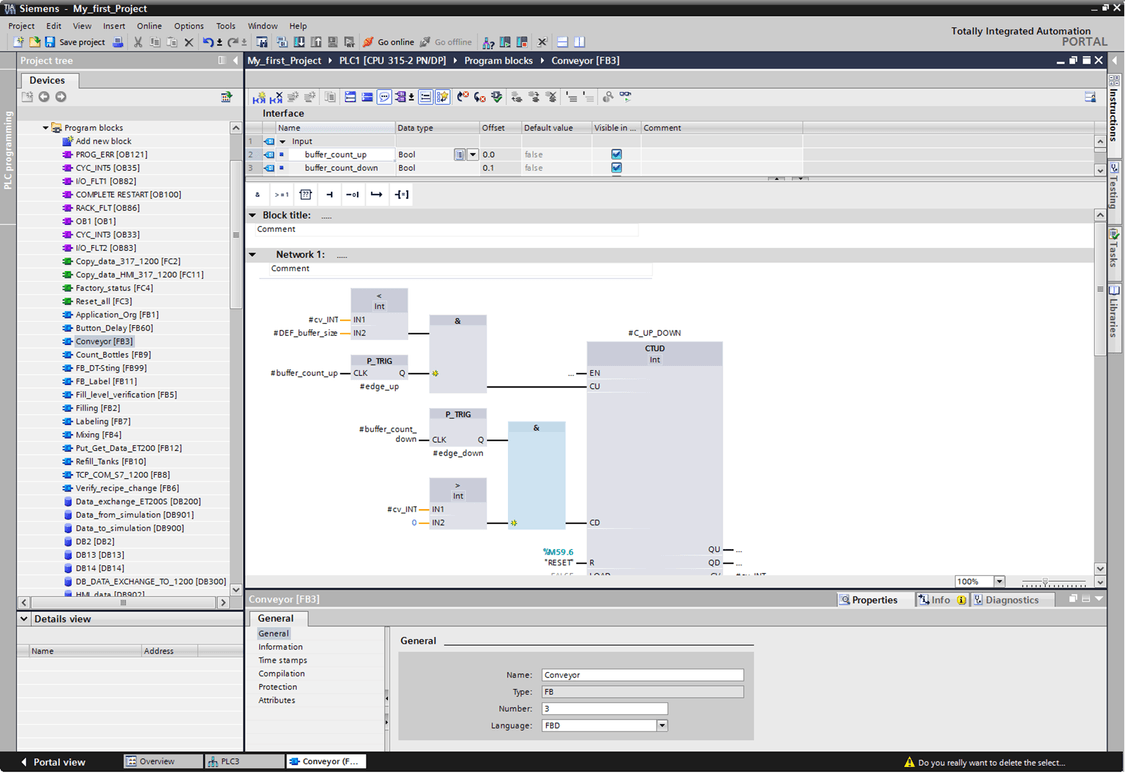

SIEMENS SIMATIC MANAGER SERIES

The series is intended for industrial automation and production. Introduced in 1958, the series has gone through four major generations, the latest being the SIMATIC S7 generation. SIMATIC is a series of programmable logic controller and automation systems, developed by Siemens. ( Learn how and when to remove this template message) For more guidance, see Wikipedia:Translation.You should also add the template to the talk page.A model attribution edit summary is Content in this edit is translated from the existing German Wikipedia article at ] see its history for attribution. You must provide copyright attribution in the edit summary accompanying your translation by providing an interlanguage link to the source of your translation.If possible, verify the text with references provided in the foreign-language article. Do not translate text that appears unreliable or low-quality.Consider adding a topic to this template: there are already 7,334 articles in the main category, and specifying |topic= will aid in categorization.Machine translation like DeepL or Google Translate is a useful starting point for translations, but translators must revise errors as necessary and confirm that the translation is accurate, rather than simply copy-pasting machine-translated text into the English Wikipedia.View a machine-translated version of the German article.

So the automation engineers can modify the project, but technichians can only read and get status from networks. I suspect we would need an authentication server witch gives sitrain rights to sirtain users. Is this at all possible with simatic manager? The technicians who are interested can allso grow and learn more about automation in this way, without the risc of corrupting the program. This way they have an extra tool to identify and solve problems like broken sensors, and give them a better understanding of the workings of the program. We would like to make it possible for them to view the status indication of the networks, but without the possibility to change the project. In our plant we would like to make it possible for the technichians in the shifts to open and view the simatic manager projects. I hope i' m posting this under the right topic.

0 kommentar(er)

0 kommentar(er)